ES-602 PCB Plate Auto Arrangement&Inspection Machine

Specification

- Front station positioning mode: Servo slide positioning

- Rear station positioning mode: Servo slide positioning

- Recycling area positioning mode: servo slide positioning

- Pick-and-place method: Four-head pick-and-place mechanism

- Working height:920mm±20mm

- Mechanical repeatability:± 0.01 mm

- Control System:PC-based 6 Axis controller

- Drive way:AC Servo motor

- working system:IPC Windows 10

- Host voltage:1φ, AC 220V 50/60Hz

- Air supply:4~6 kg/cm², flow:1500 L/hr

- Power consumption:3.0 KVA

- Flow direction: left to right, right to left

- Tray(W*D):450*400 mm

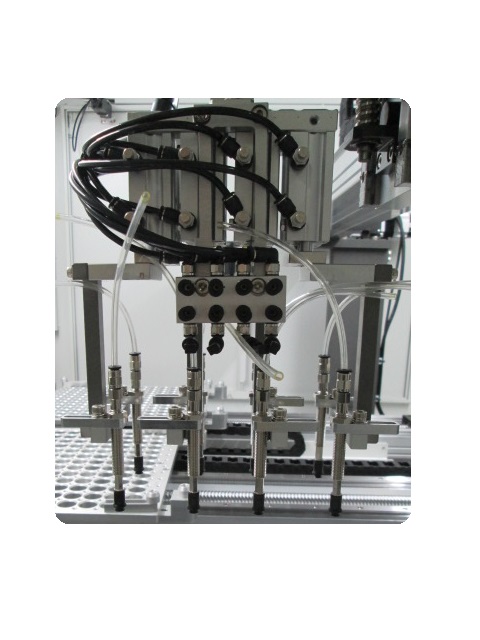

Pick and place device

Four-head pick-and-place mechanism (can pick one or four times)

Pick and place device

Automatic loading and unloading (Modular vacuum gripper, vacuum detection device, can be selected independently)

Transportation mechanism

Traverse and up / down axis, AC servo motor control

Pick and place speed

Max.400mm/sec

- With CCD identification function, classification OK and NG board, saving labor cost.

- Y, Z, and A axes adopt a gantry structure to improve repeat accuracy and pick and place speed.

- It can be used with MES system to recognize OK and NG boards

- Easy to operate and simple to set up, which effectively saves time for changing the line

- Can be used with secondary dust collection to remove dust from PCB before identification, the dust removal effect reaches 99%

| Type | Workbench | The scope of work(W*D) | Machine size W*D*H | weight(Kg) | Picture file |

| ES-602 | 3 Table | 450*400mm | 1986*1925*1980mm | 1000 | The scope of work |